At Resolute Forest Products, we know that our pulp, paper and wood products manufacturing processes have environmental impacts related primarily to the consumption of resources, air emissions, waste generation and water discharge. Our goal is to minimize those impacts by striving to go beyond legal and regulatory requirements. Our approach is based on continuous improvement and includes implementing environmental management systems (EMS) at all of our operating facilities, as well as setting annual and long-term targets, tracking our progress and reporting our performance.

The four key areas in which we monitor performance include:

Air Emissions

Resolute manages its air emissions using generally accepted pollution control technologies to minimize emissions of contaminants, such as sulfur dioxide (SO2), nitrogen oxide (NOx) and total particulate matter (TPM) concentrations that result primarily from the combustion of fuels. We have also adopted fuel switching measures, including replacing coal and heavy oil (bunker C) with cleaner fuels such as natural gas and carbon-neutral biomass. Resolute facilities have been 100% coal-free since 2014, which has helped to reduce several types of emissions, including greenhouse gas (GHG) emissions.

Resolute has made significant investments to ensure we meet and even exceed regulations. More stringent boiler emission limits came into force in the United States in January 2016 with the implementation of the U.S. Environmental Protection Agency’s new Boiler Maximum Achievable Control Technology (MACT) rule. At the end of 2023, all three of our U.S. mills subject to this rule were in compliance.

The following tables and graphics cover Resolute’s SO2, NOx and TPM emission concentrations at our pulp, paper and tissue mills from 2021 to 2023.

Significant Air Emissions

| |

Unit |

2021 |

2022 |

2023 |

| NOx |

mt |

3,426 |

2,500 |

1,471 |

| NOx intensity |

kg/mt |

1.55 |

1.26 |

0.89 |

| SO2 |

mt |

1,844 |

587 |

347 |

| SO2 intensity |

kg/mt |

0.83 |

0.30 |

0.21 |

| Total particulate matter (TPM) |

mt |

820 |

756 |

267 |

| TPM intensity |

kg/mt |

0.37 |

0.38 |

0.16 |

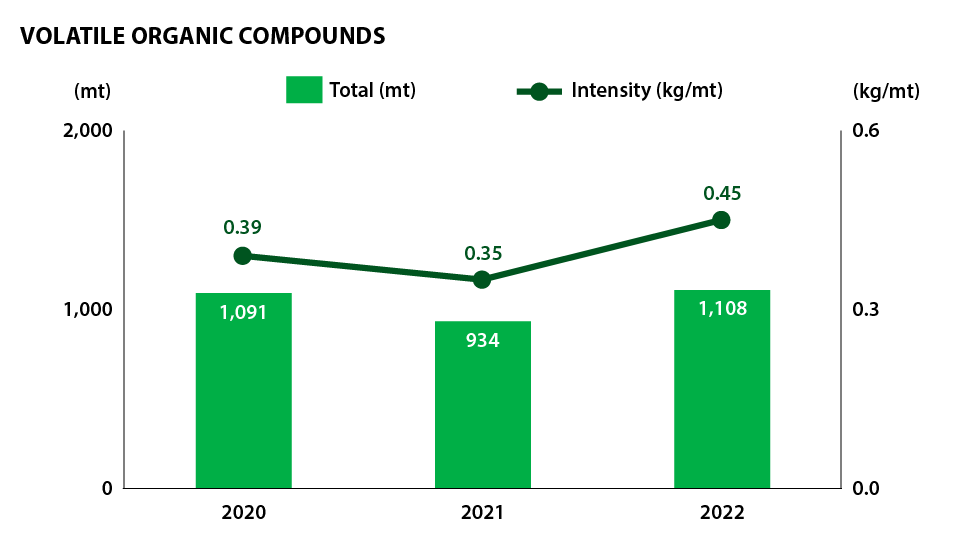

Resolute also tracks and reports volatile organic compounds (VOC), which are emitted as gases from certain solids or liquids during the manufacturing process at our pulp, paper and tissue mills.

Waste and Residue Management

Resolute is focused on reducing the waste and optimizing the residues generated by our operations. Our approach to waste management includes identifying beneficial-use alternatives, such as agricultural land spreading, in order to reduce the amount of waste sent to landfills. We also pursue process efficiencies, such as optimizing fiber use, to minimize the cost of effluent treatment.

We are committed to establishing annual fiber loss targets for each of our pulp, paper and tissue mills, and have set a company-wide target for 2023 to record fiber losses of no more than 42 kg per metric ton (mt) of production. In 2023, we recorded fiber losses at a rate of 33.7 kg per mt of production, well below the company’s annual target. Pursuant to the merger of Resolute with a subsidiary of Domtar Corporation on March 1, 2023, we are in the process of defining a fiber loss target across all companies.

Our beneficial use programs have increased the amount of waste we recycle or repurpose, reduced our environmental impact and generated cost savings. For example, we have cardboard, clean wood waste and pallets composted at certain facilities, instead of disposed of in landfill sites. In addition, a significant amount of the waste produced at our manufacturing facilities is used as fuel, reducing our reliance on fossil fuels and supporting our production of green energy. In 2023, nearly 22% of the waste we produced was recovered for use in energy production, and 73% of waste was recycled and disposed of via other elimination methods.

Waste disposal programs implemented at our operations have more than doubled the total waste that Resolute recycles or repurposes through beneficial uses like agricultural land spreading for farmland fertilization. In 2023, we redirected 3% of pulp, paper and tissue mill residues and waste toward such beneficial uses, bringing the portion of our total waste diverted from landfill to 98%.

Waste Management Performance

| |

2021 |

2022 |

2023 |

| Solid waste to landfill (mt) |

80,852 |

59,942 |

75,016 |

| Hazardous waste (% of total waste) |

< 1% |

< 1% |

< 1% |

Water Management

As pulp and paper making is a water-intensive process, we reuse water as much as possible, returning 94% to the environment. The remaining 6% is captured in the end product or evaporated during the manufacturing process. All of the water we use passes through primary and secondary effluent treatment prior to being returned to the environment. Data on water discharge is aggregated, analyzed and reported to reputable organizations, such as CDP, which awarded Resolute a management level score of "B" for our water security disclosures in 2023. For more information, visit our 2023 CDP report on water security.

Different resources help us assess current water stress levels by predicting variations due to climate change on a facility-by-facility basis. Water risk assessments are performed for all of our pulp, paper and tissue mills using the NCASI Water Tool as well as the World Business Council for Sustainable Development’s Global Water Tool™ and the World Resources Institute’s (WRI) Aqueduct platform. Near normal water availability is predicted through 2040 for all but one facility: our Hialeah (Florida) tissue mill. While our assessments predict a significant increase in future water stress for that region, the substantive business risk is rated low to medium.

More than 99% of the water we withdraw is from freshwater sources, specifically surface water. Our Menominee (Michigan) recycled pulp mill is our only facility that uses groundwater for a portion of its process water. This volume represents approximately 0.1% of the company's total water withdrawals. According to risk assessments using the WRI Aqueduct platform, Menominee is also one of two facilities currently located in a water stressed region. The second is our Sanford (Florida) tissue mill. Combined, their withdrawals and discharges account for 2.2% of the company’s total.

All of our operations and the operations of our suppliers are subject to physical, financial and regulatory risks associated with weather conditions and climate change, such as availability, reliability and accessibility of water as well as the possibility of drought. Specific risks include:

- We generate electricity at hydroelectric facilities – the water rights necessary for hydroelectric power generating facilities are subject to change;

- Environmental and health & safety regulations governing water usage, wastewater discharges and wastewater treatment systems are subject to change; and

- We draw water from various public rivers – use of government-owned waters are governed by water power agreements; some agreements are contingent on continued operation of related mills and a minimum level of capital spending.

Strategic Water-Related Partnerships

Resolute is committed to establishing key strategic partnerships in communities where we operate to mitigate water-related risks, a fact well illustrated at the Toundra Greenhouse, which we formed as a partnership in 2014 with the City of Saint-Félicien (Quebec) and local investors. Located on land adjacent to our Saint-Félicien pulp mill, the state-of-the-art greenhouse fulfills 90% of its water requirements through rainwater and snow recovery, while producing approximately 100 million cucumbers annually. It also reuses waste heat from the mill, via hot water intake, to offset its energy requirements, reducing the facilities’ respective carbon footprints.

In addition, Resolute works closely with Malbaie River Salmon Corporation in the Charlevoix region of Quebec on wildlife protection, focusing on spawning salmon in the Malbaie River. In 2018, we announced an investment of more than C$7 million to restore the dam located on the river adjacent to our Clermont (Quebec) newsprint mill.

We also participate in local and regional non-governmental organizations to collaborate on water management in watersheds where we operate, including the Organisme de bassins versants Manicouagan in the North Shore region of Quebec; the Kaministiquia River Low Flow Response Committee in Northwestern Ontario; and in the Saguenay–Lac-Saint-Jean region of Quebec: the Organisme de bassin versant Saguenay and the Organisme de bassin versant Lac-Saint-Jean. Furthermore, Resolute is a member of the Remedial Action Plan Public Advisory Committee, which works to address environmental degradation in areas of concern on Lake Superior.

Resolute is also firmly committed to managing water efficiently by establishing annual water reduction targets for each of our pulp, paper and tissue mills. In 2023, we began deepening our understanding of water-related physical risks in specific operating regions and will continue to do so in 2024.

Water Treatment

Treatment plant performance is carefully tracked, using parameters such as biochemical oxygen demand (BOD5). Non-contact cooling water that does not mix with the process effluent may be returned without treatment, but it is monitored, sampled and reported to regulatory authorities. Since the sale of the Augusta (Georgia) paper mill in 2020, all of our pulp, paper and tissue mills return their water to the environment as surface water.

It is important to our stakeholders, including the people in the communities in which we operate, as well as required by government regulations, that we use the necessary technologies to return good quality effluent to surface waters.

Key Materials Used

Our manufacturing processes require the use of chemicals to accentuate the brightness of our pulp, to treat our effluent and for pH control. As the use of chemicals relates to both environmental stewardship and worker health and safety, it is a major focus across all of our operations.

Chemical suppliers are required to maintain certain health, safety and environmental standards when transporting, delivering and handling chemicals for Resolute. Risk reduction also plays a role in which chemicals are selected for use in the manufacturing process, including the form for particularly dangerous or toxic substances.

To avoid chemical incidents, guidelines have been developed to require the use of protective suits to prevent negative impacts. All new chemicals entering a mill undergo an assessment to identify any potentially negative effects for employees, risks to health and safety and potential impacts on the effluent treatment plant. Safety audits conducted every three to four years at each operation consider the chemicals used and mill-specific procedures, and environmental risk assessments are conducted for each new chemical that enters the mill. This includes severity of risks and thresholds at which increased management would be necessary.

Representatives from Operations and Environment work together to assess the risk of different chemicals. Some chemicals have been banned entirely due to their toxicity, although this is not required by law, while other substances have been chosen specifically to reduce risk and mitigate environmental impacts. In addition, inventories are carefully tracked to quickly identify spills and abnormal consumption. Chemical management is verified as part of our environmental risk and compliance systems, where each facility is audited every three years.

In 2020, we implemented new guidelines relating to the review of procurement contracts as well as Guidelines for High-Risk Environmental Contracts; all new chemicals purchased are subject to approval of Resolute's corporate environmental and product stewardship director. In 2021, we also completed the implementation of the Verisk 3E Connect tracking system – the new database is used to inform customer requests and other product stewardship initiatives and to better track the conformity of our supply chain.

The table below lists the key chemicals we use in our operations. This data, provided by the suppliers, represents the total weight of these substances delivered to our pulp, paper and tissue operations over the reporting year.

Chemical Usage by Year

Dried metric tons (dmt) |

2021 |

2022 |

2023 |

| Borol |

723 |

952 |

733 |

| Hydrogen peroxide |

2,663 |

2,489 |

3,244 |

| Methanol |

4,068 |

2,623 |

2,990 |

| Phosphoric acid |

509 |

583 |

319 |

| Sodium bisulfite |

6,399 |

5,877 |

6,451 |

| Sodium chlorate |

36,485 |

21,383 |

24,137 |

| Sodium hydrosulfite |

354 |

164 |

139 |

| Sodium hydroxide |

14,463 |

2,805 |

2,863 |

| Sulfuric acid |

30,039 |

18,047 |

18,983 |