At Resolute Forest Products, environmental performance is managed at the local level with oversight by the organization’s top management. Our vice president, Environment, Energy and Innovation, has overall responsibility for risks and opportunities at the mill level, while our vice president, Forestry and Woodlands Operations, oversees our forest operations. A top-down approach is in place for the analysis of risks and opportunities, which relate primarily to stategic, operational, financial, legal and compliance issues.

Guided by the company’s Environmental Policy, our environment coordinators and facility managers have on-the-ground responsibility for compliance with local laws and regulations and for facilitating continuous improvement. Corporate environment managers and coordinators work closely with each mill environment coordinator to identify and manage the issues most relevant to specific operations.

On an annual basis, each facility sets reduction targets for water use and fiber losses. In addition, facilities set targets on specific local issues, an approach that reflects the different geographic and technological realities of each operation. Key performance indicators (KPIs) are monitored at both the facility and corporate levels. At the facility level, greenhouse gas (GHG) emissions, water usage, air emissions and waste generation are the most material areas of focus. We monitor our performance closely to maintain continuous improvement across our key performance indicators and conduct regular environmental risk audits as part of our proactive, preventive approach to environmental management. Information on these KPIs is aggregated, analyzed and, in some cases, reported to organizations such as CDP.

ISO 14001:2015 Environmental Management Systems

All of our operations are certified, or in the process of being certified, to the ISO 14001:2015 environmental management systems (EMS) standard.1 We are in the process of implementing EMS at our Glenwood (Arkansas) sawmill and our Hagerstown (Maryland) tissue converting facility, a process we are striving to complete in 2023. Resolute completed the transition to the ISO 14001:2015 environmental management system certification at our certified operations in 2019, working to comply with the increasingly stringent and far-reaching requirements of the new standard.

Proactive Approach to Preventing Environmental Incidents

Our employees have worked collaboratively across all levels of the organization to instill a preventive and proactive approach to environmental management, including developing and implementing environmental risk audits designed to identify potential non-compliances or environmental risks before incidents occur.

In 2022, we trained 184 of our directors, managers and superintendents to reinforce our commitment to environmental management and compliance. Training took place via four virtual sessions led by our Legal team.

To reinforce our commitment to environmental incident prevention, we also have in place a 360-degree risk assessment system, one-on-one environmental meetings with employees, employee meetings that highlight environmental incidents and prevention, and a robust near-miss reporting system based on our successful health and safety incident management approach.

In the rare event that an environmental incident does occur, our operations and Environment group review all incident investigations and action plans. Our incident management approach includes a comprehensive tracking system to ensure efficient reporting, as well as specific procedures for the internal communication of environmental incidents with the purpose of sharing key learnings between facilities. A formal investigation is always required so that efficient preventive measures can be put in place.

In late 2012, we changed our reporting procedures following a senior management request for more transparency and consistency in environmental incident communications. Accordingly, the Environment group developed a policy that includes reporting methods and parameters to support information sharing and continuous improvement. In order to compare "apples to apples," we now classify significant (by volume) spills uniformly across operations, using the most stringent local laws and regulations as our baseline. Notices of violation (the documents issued by government entities to inform organizations of their violations as well as the associated administrative penalties, fines or sanctions) are also addressed through this policy framework.

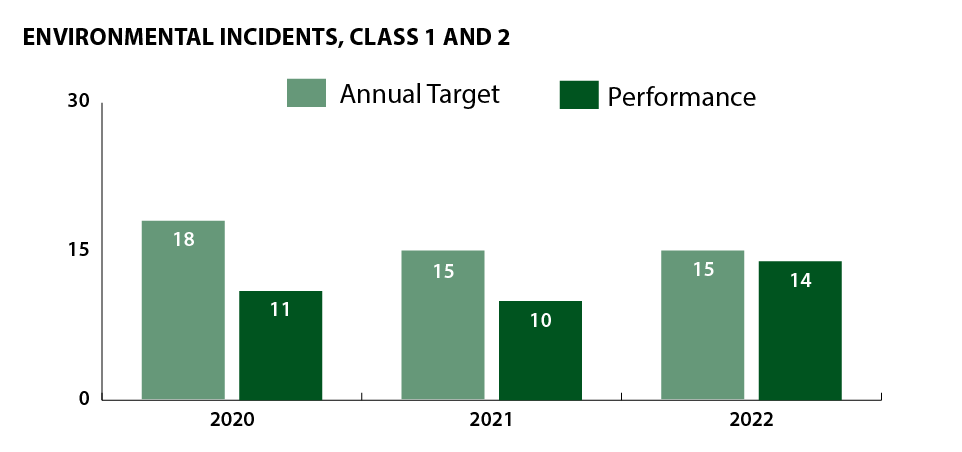

In 2022, we recorded 14 environmental incidents across the company, below our target of 15 incidents and a 42% reduction over 2015. As we continue to work toward our long-term aspirational goal of zero incidents, our 2023 target is to record 15 incidents or less.

Consistent knowledge transfer and the sharing of best practices following an environmental incident have revolutionized the way that Resolute’s operations investigate root causes and develop preventive practices. Operations where a similar incident might occur must evaluate their risk and implement preventive measures that are tracked at the corporate level. Regular conference calls and individual follow-up meetings have been instrumental in the success of this preventive and proactive approach, which represents a successful cultural shift for the company.

1 Includes 14 ISO 14001-certified pulp, paper and tissue mills, 18 wood products facilities, 1 hydroelectric generation and transmission network, and 7 woodlands operations certified to ISO 14001 out of Resolute’s 14 pulp, paper and tissue mills, 20 wood products facilities, 1 hydroelectric generation and transmission network, and 7 woodlands operations, and 1 tissue converting facility.

2 Material environmental contingencies are disclosed in the footnotes to the company's consolidated financial statements in its Annual Report on Form 10-K for the year ended December 31, 2021. Certain additional proceedings are also disclosed under the heading "Item 3 – Legal Proceedings" in the Form 10-K.