Resolute Forest Products’ commitment to climate action is focused on green energy and exploring ways to enhance our overall energy efficiency. Optimizing the use of renewable energy sources such as hydroelectricity and carbon-neutral biomass, while reducing consumption of fossil fuels, is a key element of our strategy to improve our carbon footprint.

Our focus on improving energy efficiency and replacing high-emission fuels like coal with less-carbon-intensive fuels also places Resolute ahead of potential regulations, positioning the company as a leader in greenhouse gas (GHG) reductions and in the development of new, sustainable products that have a lower carbon footprint.

Energy-use and other projects that have an impact on energy consumption are linked with Resolute’s carbon management activities and are consequently managed through the organizational structures and procedures described on the Climate Change and Energy page. Data is collected at the mill level and aggregated by our corporate Environment team.

Going 100% Coal-Free and Using Less Carbon-Intensive Fuels

Replacing high-emission fuels like coal with less-carbon-intensive fuels benefits both the environment and our bottom line. In 2014, we replaced the remaining coal used at our operations with natural gas, a less-carbon-intensive fuel, becoming scope 1 coal-free at 100% of our facilities. Over the years, we have also reduced bunker C oil use at our Clermont, Dolbeau and Saint-Félicien mills in Quebec, and initiatives are currently underway at several other facilities to reduce the use of natural gas in favor of biomass or electricity utilization.

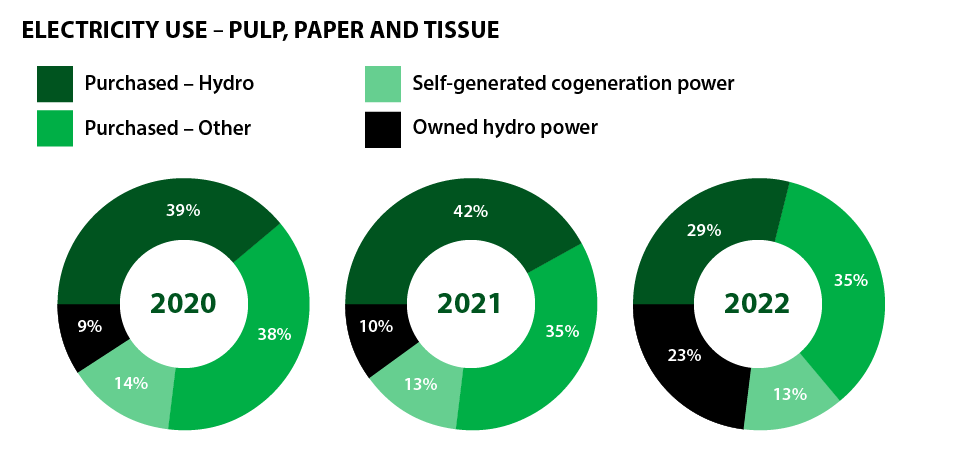

The energy used in Resolute’s pulp and paper production comes primarily from its network of seven hydroelectric and five cogeneration facilities, and the balance of electricity and fuel is purchased from external suppliers. Cogeneration refers to the simultaneous generation of electricity and steam, which allows us to extract more energy from a given amount of fuel. In 2022, we also added a thermal power generating facility to our network in Senneterre, Quebec.

More than three quarters of our total energy needs (79% / 12,091 GWh) in 2022 were generated from renewable sources, such as hydroelectricity and biomass.

Fuel Energy and Electricity Consumption

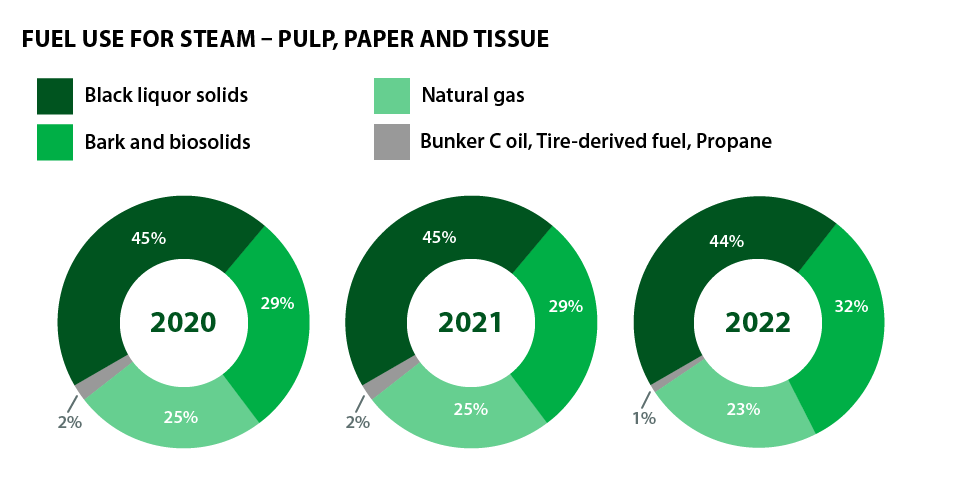

At Resolute, 75% of fuel energy usage (7,913 GWh) is derived from carbon-neutral biomass.1 By utilizing bark, black liquor and biosolids for energy instead of sending these materials to landfill, Resolute is able to reduce fossil fuel consumption, avoiding the GHG emissions associated with their use. A small portion of our fuel energy is sourced from other alternative energy fuels, primarily used tires, which diverts these materials from landfills and recovers the energy value.

Resolute produces 38% of its electricity needs internally (owned and self-generated), mostly from renewable sources. The remainder is purchased from third parties. In 2022, the combined amount of purchased and self-generated electricity we used in our pulp and paper mills totaled 4,720 GWh. We also sold an additional 676 GWh of self-generated electricity to external stakeholders.

We see rising energy costs and power supply disruptions as risks that must be managed. For this reason, we continue to focus on improving the energy efficiency of our mills and maximizing internal cogeneration of heat and power from renewable sources. For more information on climate and energy-related risks, please see our CDP Climate disclosure.

Fuel Energy and Electricity Consumption

| |

2020 |

2021 |

2022 |

| Fuel energy used (TJ) |

54,456 |

51,606 |

37,881 |

| Electricity used (TJ) |

19,175 |

18,027 |

16,990 |

| Purchased electricity (GWh) |

3,860 |

3,620 |

3,679 |

| Self-generated electricity (GWh) |

2,323 |

2,060 |

1,717 |

Renewable energy as a % of total energy

(including purchased electricity) |

77% |

77% |

79% |

Using and Producing Electricity

Continuous Improvement

We are constantly evaluating and improving our manufacturing processes to optimize energy efficiency and reduce our consumption of fuel, steam and electricity. This, in turn, reduces our scope 1 and 2 GHG emissions and helps to improve our cost structure and competitive position.

Our climate change mitigation efforts received extensive recognition in 2022. Among the many accolades, the World Sustainability Awards highly commended Resolute in the Sustainability Excellence category for our commitment to and leadership in clean energy production and for our GHG reductions. In addition, and for the second year in a row, the Big Awards for Business recognized Resolute with the Sustainability Leadership Award for taking bold actions to reduce GHG emissions, combat climate change, and making sustainability an integral part of our business practice.

We will continue to focus on renewable energy sources by increasing the use of biomass and optimizing our cogeneration business, among other advances.

1 Does not include wood products. Includes bark and biosolids from our water treatment plants, as well as black liquor, rail ties and CRD material.